Access industrial-grade spray foam and continuous roof systems in Odessa that control heat, air, and moisture in one assembly per IECC/IRC and IBC. Choose open-cell to optimize vented attics and sound control, or closed-cell for higher R-value, Class II vapor control, and stability. We protect per IECC R402.4 and validate with blower-door testing. UV-protective coatings shield SPF per ASTM and CRRC. Secure application comply with OSHA and IRC R316. Keep going to see choices, value, and guarantee specifics.

Essential Points

- SPF operates effectively in Permian Basin challenging climate, efficiently managing climate control and moisture levels while complying with IECC/IRC standards for air-sealing and vapor-control.

- Open-cell insulation provides ventilation to wall cavities and attic areas, while closed-cell delivers superior R-value, increased structural strength, and functions as a Class II vapor retarder at installation to code thickness.

- Continuous SPF roofs with UV-resistant coatings reduce leaks, improve heat reflection, and satisfy ASTM and IBC standards.

- The team maintain OSHA safety standards and implement correct containment procedures, carrying out preliminary testing, maintaining equipment controls, and confirming material thickness and airtightness through comprehensive blower-door testing.

- Anticipate reduced HVAC runtime and three to seven year payback; verified ACH50, R-values, and warranties qualify for code compliance and rebates.

Why Spray Foam Works in the Permian Basin Climate

Despite West Texas sees dramatic climate shifts from blistering summers to chilly snaps and dust-laden winds, spray polyurethane foam (SPF) delivers dependable results because it controls heat, air, and moisture in one assembly. You get heat protection from a seamless, air-impermeable layer that limits thermal and air gains following IECC and IRC N1102/IECC R402 air-sealing criteria. SPF additionally minimizes moisture migration by preserving warm-side temperatures above dew point, meeting IRC R701.3 vapor control intent and IBC 1403 weather protection.

Open-Cell versus Closed-Cell: Making the Right Foam Choice

Prior to picking a foam type, compare its specifications to your building requirements, regulations, and cost considerations. Open-cell spray polyurethane foam (ocSPF) provides excellent moisture transmission and sound control, ideal for attic spaces and internal partitions. It generally offers R-values between 3.6 and 4 per inch, so plan thickness to achieve IECC/IRC R-values. ccSPF delivers enhanced R-values of 6 to 7 per inch, structural strength, and an excellent air seal that reduces thermal bridging. In mixed-dry climate zones like West Texas, ccSPF can function as a Class II vapor retarder at 1.5-2 inches; check dew-point control per IRC R702.7 and building envelope assemblies.

It's essential to maintain fire and thermal barrier protection as specified in IRC R316 and manufacturer evaluation reports. Make certain substrate moisture is within spec, provide adequate ventilation throughout the installation process, and wear appropriate PPE to protect against isocyanate exposure.

Advanced Roof Coatings for Superior Protection

You have the option to install a unified waterproof membrane that prevents fastener penetrations and seams, reducing leak risk and meeting IBC performance standards for roof coverings. With ultraviolet-protective coatings (including acrylic, silicone, or polyurethane), you shield SPF from UV degradation and maintain reflectance per CRRC/ENERGY STAR ratings where applicable. Adhere to manufacturer data sheets, ASTM D6083/D6694 classifications, and OSHA fall-protection protocols during installation for safe, code-aligned performance.

Key Benefits of Monolithic Membranes

When a roof coating hardens into a monolithic membrane, it removes seams-the weakest link in most assemblies-and forms a uninterrupted, watertight barrier that stands up to wind-driven rain and standing water. You get monolithic durability that limits capillary intrusion at penetrations, junctions, and fasteners. By removing lap joints, you reduce failure points and satisfy IBC Section 1507 performance standards for roof coverings and IECC air-control objectives through continuous insulation continuity.

This unified system improves wind resistance when installed according to FM Global approvals and ANSI/SPRI standards, helping maintain attachment integrity during Odessa's wind events. You'll benefit from simplified maintenance, as inspections target individual damage points as opposed to miles of seams. Make sure to specify appropriate surface prep, moisture testing, and wet-mil verification to reach specified dry-film thickness, adhesion, and safe, code-compliant performance.

UV-Resistant Waterproofing Layers

To maximize a monolithic membrane's protection, you should implement UV-resistant waterproofing materials that don't degrade under Odessa's strong UV radiation. Choose elastomeric topcoats formulated with UV stabilizers and reflective additives to achieve cool-roof performance targets. Ensure coatings meet IRC/IBC energy provisions and ASHRAE 90.1 for solar performance and thermal emittance; consult CRRC ratings to verify SRI. For spray polyurethane foam, implement a compatible aliphatic polyurethane or silicone topcoat at the manufacturer's minimum dry film thickness, maintaining slope-to-drain.

Comply with ASTM D6694 for silicone guidelines, and conduct field adhesion testing following ASTM D4541. Verify substrate moisture content and ambient parameters in accordance with OSHA safety requirements and SDS. Check for discontinuities, gaps, and border seals; fix without delay to preserve uninterrupted, moisture-resistant integrity.

Air Sealing Solutions for Comfort and Health

Though frequently disregarded, comprehensive air sealing is essential to healthier, more comfortable buildings in Odessa's hot and gusty conditions. By managing uncontrolled infiltration and exfiltration per IRC N1102/IECC requirements, you minimize dust, pollen, and outdoor contaminants, preserving indoor air quality and inhabitant wellness. Spray foam insulation serves as both an air barrier and Class II vapor retarder when installed to code-specified thickness, controlling moisture-laden air movement that can drive dampness and fungal growth.

You'll additionally minimize thermal variations and drafts by minimizing thermal bridging at building junction points, rim joists, and wall-roof connections. Perform blower door tests (IECC R402.4) to verify airtightness targets and identify leakage pathways. Seal penetrations around ducts, can lights, and plumbing with fire-rated materials where required (IRC R302). Be sure to provide ventilation per ASHRAE 62.2 for balanced fresh air.

Energy Savings, ROI, and Utility Rebates

Lower utility expenses and maintain consistent billing by focusing on the primary energy loss points first: the structure's exterior and air ducts. Closed-cell and open-cell spray foam minimize air leakage in line with IECC requirements and thoroughly seal ducts following IRC/IMC guidelines, leading to decreased HVAC usage and peak demand. You can expect seasonal energy savings as spray foam reduces hot season thermal transfer and winter thermal loss, improving both sensible and latent control.

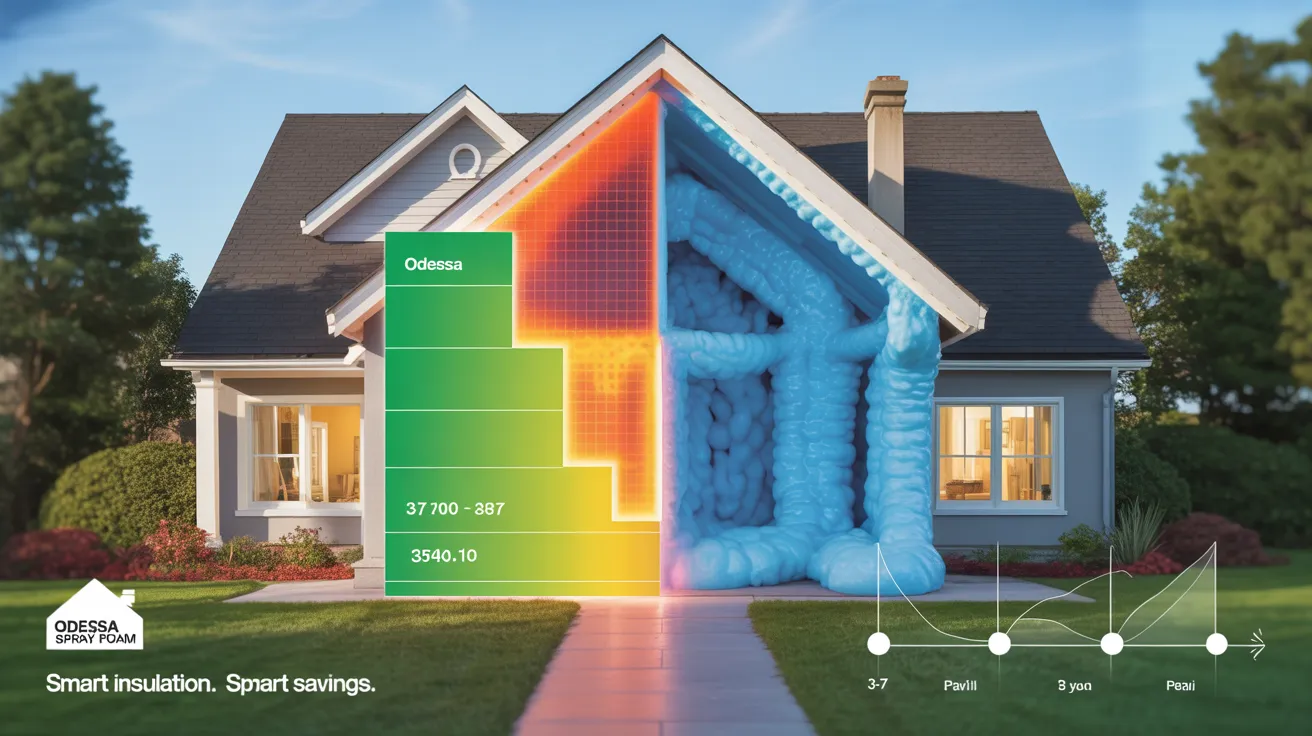

Calculate ROI by correlating lower kWh/therms with Odessa utility rates. Typical simple payback falls between 3-7 years, with continuing payback continuing as energy prices rise. Verify R-values, ACH50 results, and duct leakage to outside (CFM25) to quantify performance. Check Oncor and local co-op rebate portals for energy-saving bonuses, energy improvement financing, and load management rewards. Log insulation certificates, combustion safety tests, and code compliance to validate requirements.

New Build and Renovation Applications

If you're working on new construction or renovating an existing property, spray foam adapts to different scenarios while maintaining its purpose: an effective solution for air sealing, insulation, and moisture management. In new construction, you can detail continuous insulation at walls and roof areas, align the air barrier with the thermal layer, and satisfy building code requirements for thermal performance. You'll plan for temperature-controlled attics, sealed floor systems, and regulated ventilation instead of passive foundation vents, while combining foam with moisture barriers as needed.

During retrofit projects, you need to identify and fix existing gaps, confirm substrate dryness, and conduct combustion safety using CAZ testing. You'll properly seal crawlspaces, seal off foundation vents as per code, and install mechanical ventilation to meet ASHRAE 62.2. Using closed-cell foam creates structural strength and flood resilience; whereas open-cell works best for sound attenuation and moisture management.

Our Installation Process and Warranty Options

Here's our detailed installation procedure: substrate inspection, moisture level testing, ventilation system preparation, and spray foam installation to meet required R-values per IRC/IECC and manufacturer data sheets. We prepare the jobsite with proper barriers, PPE, fire safety checks, and ventilation to meet OSHA/NIOSH standards and local fire-code regulations. We'll explain warranty coverage options, including materials and installation guarantees, what's covered (bonding, density, R-value), exceptions, and documentation needed for claims.

Installation Guide

Prior to applying any amount of foam inside your Odessa property, we verify substrates, safety, and scope according to IRC/IBC and manufacturer specifications, then explain the plan and warranty terms. We verify substrate temperature, adhesion, and moisture targets, document R-value goals according to IECC, and determine open- or closed-cell based on application.

Next, we carrying out foam mixture preparation and equipment calibration following manufacturer ratios. We track hose temperatures and pressure levels, and perform a test shot to evaluate foam expansion and reaction. Installation continues using controlled layers, adhering to ventilation requirements and ignition barrier specifications as specified in IRC R316. We verify thickness using depth meters, properly seal connection points, and photo-document the application.

As a final step, we carry out complete cure verifications, issue a detailed workmanship guarantee, and record product warranties along with serial numbers and batch information.

Construction Site Prep and Safety Protocol

Although every home is different, our crews follow standardized jobsite prep procedures according to OSHA 29 CFR 1926 and manufacturer requirements: we establish work zone isolation using poly containment, establish negative air following ASHRAE 62.2 specifications, and display access control with PPE protocols (full-face respirators, gloves, Tyvek). We utilize lockout/tagout protocols for HVAC and electrical when necessary, and we verify make-up air to prevent combustion appliance backdrafting per IRC M1503. We place Class ABC extinguishers, assess SDS sheets, and carry out hazard communication briefings under 29 CFR 1910.1200. To guarantee site safety, we shield adjacent finishes, protect ignition sources, and use intrinsically safe lighting. We track VOCs and isocyanate exposure, keep clear egress routes, and log daily JHAs. Upon curing, we air out, remove containment, and perform a final safety assessment.

Warranty Coverage Options

Although performance starts with correct prep and installation, your protection is enhanced by comprehensive warranties adapted to Odessa's environmental conditions and building codes. You obtain a material warranty from the manufacturer and a contractor installation warranty, both conforming to IRC/IBC and IECC specifications for spray foam, fire barriers, and roofing systems. Enhanced warranty options are possible when you pair SPF with certified protective layers and arrange annual maintenance visits.

Protection encompasses key spray foam insulation aspects such as adhesion properties, density ratings, R-value stability, and water intrusion protection, provided proper code-compliant ventilation and moisture control is maintained. We carefully record surface moisture measurements, lift thickness specifications, and cure temperatures to preserve claim qualification. Warranty transferability choices allow benefits to continue to future homeowners with proper maintenance documentation. Additional coverage for ultraviolet exposure and hail impact can be added. Coverage limitations cover improper use, non-approved penetrations, and maintenance deferrals.

Common Questions

Are Financing Options and Payment Plans Available for Insulation Projects?

Indeed, you have access to flexible financing and structured payment plans. We provide features such as 0% same-as-cash promotions, deferred payment options, and low-APR financing, subject to credit approval. We stage draws according to project phases (prep, installation, final inspection) and align with code-compliant scope per IRC/IECC R-values and fire safety (NFPA 286/ASTM E84). You'll receive a transparent cost breakdown, lien notices, and warranty terms. Submit your application online or in person; we'll process your pre-qualification while maintaining project timing.

Are Your Technicians Certified and Background-Checked for On-Site Work?

You're protected by carefully screened specialists. Imagine a carefully managed worksite where each piece of equipment works flawlessly; you operate safely because each technician completes detailed background verification and maintains professional certifications. They fulfill OSHA 10/30 safety requirements, follow EPA RRP and ICC/IRC insulation regulations, and maintain NFPA 286/285 fire-testing protocols for assemblies. You get credentialed teams, verified qualifications, and leadership verification, confirming compliant implementations, adequate clearances, and optimal results with traceable records.

How Soon Can We Schedule Your On-Site Assessment in Odessa?

We're available to book your on-site assessment as soon as today, based on today's schedule, or within 24-48 hours. We also provide weekend assessments. You'll get a Level 1 pre-screen per IRC R316 and OSHA 29 CFR 1910.134, verifying ventilation, ignition sources, and access. We'll evaluate substrate moisture (≤19%), ambient temp/humidity, and roof load limits. We'll provide you with a detailed plan, safety plan, and permit guidance. Get in touch now to lock in your time.

What Brands and Chemical Formulations of Foam Do You Use?

Similar to a well-tuned engine, you can expect consistent performance from our specified brands and formulations. You'll choose certified polyurethane blends from Huntsman/Demilec, Carlisle, and ICP. We apply closed cell chemistries (2 lb, HFO-blown, Class II vapor retarder) and open-cell systems, all ICC-ES evaluated (ESR- reports) and compliant with IRC/IBC, NFPA 286, and ASTM E84. You get proper ignition/thermal barriers per code, manufacturer-specified lift thickness, substrate temps, and safety equipment-guided safety during installation and curing.

Can You Handle HOA Requirements and Permit Processing?

Indeed. You'll be assigned dedicated HOA liaisons to analyze CC&Rs, handle architectural review packets, and follow approvals. We handle permit management end-to-end: property layouts, product data sheets, ICC-ES reports, and code-compliant energy standards per IRC/IECC. We schedule inspections, copyright OSHA-compliant jobsite practices, and document NFPA 285/UL listings where applicable. You'll get stamped drawings if required, plus detailed specifications, ventilation plans, and disposal manifests, securing full jurisdictional compliance and a complete closeout.

Wrapping Up

You're not following illusions-you're designing comfort. In Odessa's weather, SPF meets IECC/IRC R-values and ASHRAE 90.1 standards, while seamless roof coatings deliver Title 24-grade reflectance and ASTM D6083 strength. You'll achieve tighter air barriers per ASTM E2178/E2357, Class A solutions per ASTM E84, and vapor control to click here IRC R702.7. We follow OSHA 1910/1926 PPE and ventilation protocols, then back implementations with documented warranties. Prepared to achieve savings, convenience, and code adherence-excluding issues or guesswork?